| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

| Home | Presses | Intro | Site Map | P.R. | Chemicals | Answers |

|

| Prices | Specials | How To | Bullets | B.Makers | Books | Classified | |

| Topics | Jackets | Terms | Training | Software | Products | Contact us |

Basic Package |

|||||||||

What do I need?

What do I need?

Complete System Quotes (select green dot to download): For calibers .102 to .458-in, up to 1.3-in long Note: Since Corbin makes ANY diameter, the dies are not listed by caliber but by style of bullet. Determine the bullet type, and select dies to make it, then specify caliber when you order. You can swage a lead or jacketed bullet in the range of . 102 to .458 diameter, in any of the standard nose (ogive) shapes such as 1-E, 3/4-E, 6-S or ULD (see design page) with the CSP-1 press and type -S dies. You can order custom diameters and nose shapes, rebated boattails, and lead tips with the options listed. Powder metal bullets can also be formed by the addition of the proper powder handling accessories, discussed on the powder metals page. If the bullet you want to make is in the above caliber range, not over 1.3 inches long, and uses a malleable material that forms with the same pressure as soft lead (Bhn 5-6) then the -S dies are what you want to examine. The number and kind of -S dies you want will depend on the shapes and styles you wish to swage. See die instructions to understand the purpose and use of the different swage dies. For calibers .458 to 1-in. or longer than 1.3 inches

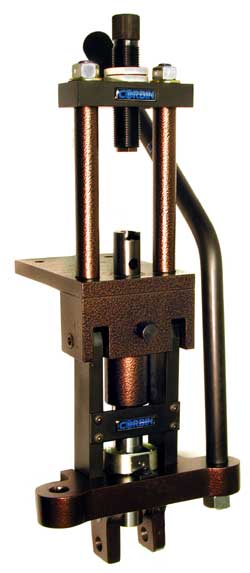

To swage longer or heavier or larger diameter bullets than will work with the S-press and -S type dies, you will need to select either the CSP-2 Mega Mite hand press or the CHP-1 Hydro Press. These presses can also make the same bullets as the ones built by the S-press and dies, if you use the appropriate -H dies. The decision of whether to use the large hand press, or the Hydro-Press, depends on details of the bullet and jacket. If you want to make long, heavy and pointed bullets such as the 50 BMG, using copper tubing for jackets, the Hydro Press is a better choice. It takes the work out of swaging. It is not a fully automated production system, which runs without operator attention, but a well-engineered manually fed press which, when set for a given stroke, pressure, and dwell time, can be used by anyone to produce the same high quality results as would be obtained by an expert bullet maker. The Hydro-Press uses sensors, transducers, and precision electronics to repeat each stroke exactly the same way, and to consistently duplicate the procedure as if an expert were operating it. Yet the actual operator only needs to drop a part into the die and press large, clearly marked buttons. All the skill is in setting up the press, rather than running it. Some operations are not practical for the hand press, such as punching and drawing copper strip that is thicker than about .030 inches or wider than about 1.25 inches, or extruding practical lengths of lead wire. These are simple tasks for the Hydro-Press. Very long, pointed bullets are much easier to form in the Hydro-Press because you have full power anywhere in the stroke, and the stroke itself can be defined by user-set stop and start (and loading position) points anywhere in a 6-inch range. A hand press only has maximum power at the end of the stroke, and the start and stop points are fixed by the mechanical design. Production speed and ease of use

There is no question that the Hydro-Press is the winning choice. People who have injuries or disabilities that would prevent the use of a hand press for production work can drop parts into the die and press the buttons on the power press with ease. The fact that the stroke can be defined for the purpose and instantly changed for another job, with full power anywhere within the six-inch travel range, and the precision timing, adjustable force, and precisely set pressure levels all combine to make the Hydro-Press the choice of most custom bullet firms, research labs and military development facilities. However, the CSP-2 Mega Mite press is a good stepping stone and starting point IF you might consider stepping up to the Hydro-Press at some later time, but want to get started with the same kind of dies now. Using the hand press (CSP-2) means you can simply screw the -H type dies and punches into the Hydro-Press later. If you were to start with the CSP-1 S-press, which uses -S dies, you would need to duplicate them in -H type to move up to the larger presses later. (It is, of course, handy to have more than one press and die on hand for the same job, since you can set up a sort of mini-production line, doing easy or low pressure steps in the smaller press and performing the steps that take more effort in the power press.) CSP-1 S-Press, Swaging and Benchrest Reloading Press This is the world's most popular swaging press, much faster and easier to operate than a reloading press for forming bullets. Mount directly to your bench top, or get the self-supporting floor stand for more storage and a little easier operation. Roller bearings, steel construction, hard-chromed ram, precision beyond anything you've seen on a dealer's shelf! Prices FJFB-3-S Three-die swaging set, jacketed and lead, open tip or FMJ. We just need to know the caliber, weight range you would like, and the ogive shape (standard spitzer rifle bullets are 6-S or, for long range target shooting, the ULD or Ultra Low Drag nose; standard big bore .44-45 rifle is 1-E ogive, and standard handgun calibers are either the TC (truncated conical) or the 3/4-E ogive. Other shapes are available with a modest tooling/setup cost. Unusual or non-standard diameters are additional, as are calibers below .224 diameter such as the .172, .19, .142, and .204 (5mm). FJFB-3-S Prices CSL-2 Corbin Swage Lube, 2-oz. The standard of the industry for nearly 30 years, also an excellent case sizing lube. Swage Lube doesn't diesel like regular petroleum based sizing lubes, and it has a far higher film strength under pressure. Prices LW-10 Lead Wire, 70000 grain spool in appropriate size. Pure lead wire is more dense, swages easier, and yields a higher BC bullet. Available in all the appropriate sizes for .14 to .512 caliber (although above .458 you will need to switch to the larger -H dies and Mega Mite or larger presses). Prices PCS-1 Precision Core Cutter, for above wire. Cut lead wire quickly to preset lengths, accurately adjustable, and then swage it to exact weight and size in the first die of the 3-die set. Cutter uses interchangeable, hardened die inserts for long life and closer cutting. Prices Select the appropriate length and caliber of bullet jacket, and add this to the order. If the caliber you want to make, or the length of jacket, is not available from standard supplies, then you may wish to choose one of these other methods of getting the desired length and/or caliber:

If you have any questions about the size of wire or best way to obtain jackets, contact us and we'll work out the best solution to make your desired bullet. | |||||||||

| |||||||||

|

Your 3-die set (FJFB-3-S) is a matched set of the core swage, core seater, and point forming die with their respective punches. Click on the little green circle beside the die name for detailed information on how each of these dies helps you make a better bullet and how they work in concert with each other.

The dies and punches are marked with "S", "C", and "P" to indicate the core swage, core seater, and point former respectively. The core swage has the smallest diameter bore and punches, and the die has three bleed holes around the circumference. The core seater looks like the core swage but it has no bleed holes, has a larger bore diameter (about 0.0005 inches or so smaller than the caliber), and has an external punch that either fits inside your jacket (for open tip bullets) or fits the die bore (for soft nose or lead tip styles). The point forming die has a semi-blind cavity hole fitted with a thin ejection pin wire punch at one end. It is full diameter for the caliber. The bullet goes into this die nose first, and goes into the core seater base first. A simplified instruction sheet comes with the die set, explaining how the dies work and telling you how to set them up and use them. More information is found in the Corbin Handbook of Bullet Swaging, and in the other books on bullet design from Corbin. | |||||||||

|

| Home Page | Price List | Site Map | New Products | Q&A | Terminology | |

| Retirement | Specials | Real Estate | Software | How to swage | CS Die | PF Die |