|

Bullet Swaging Diagrams

|

|

|

|

|

|

Bullets can be made from copper strip and lead wire, using this equipment (for flat base open tip or lead tip bullets):

- CSP-1 S-Press

- JMK-1-S jacket maker kit

- FJFB-3-S 3-die set (open tip)

-OR-

- LTFB-4-S 4-die set (open or lead tip)

- CU-50 or CU-5 copper strip

- CSL-2 swage lube

- LW-10 lead wire

- PCS-1 core cutter

|

Corbin CU-50

Corbin CU-5

|

From copper strip to finished rifle bullet:

|

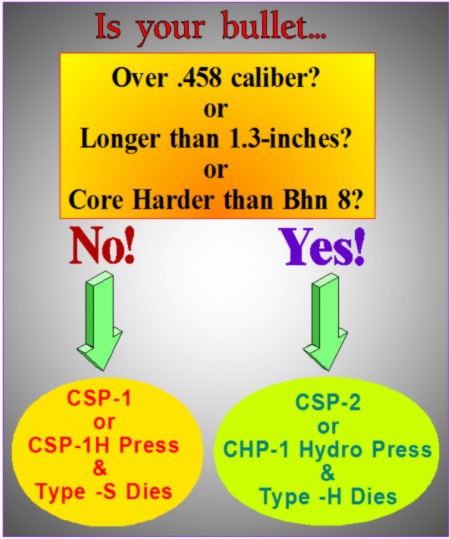

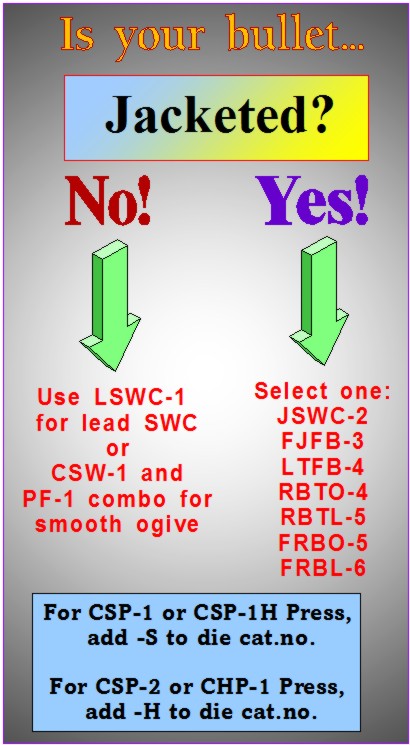

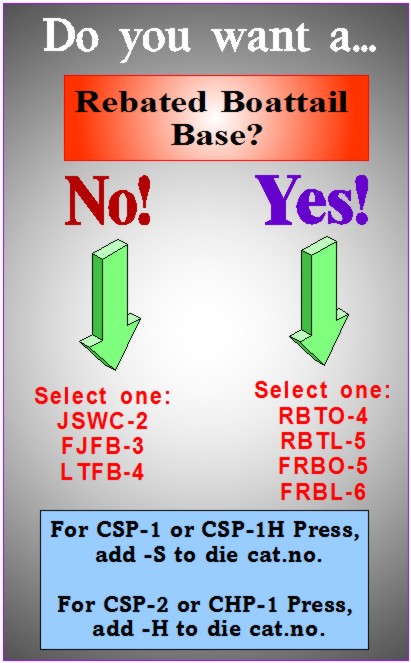

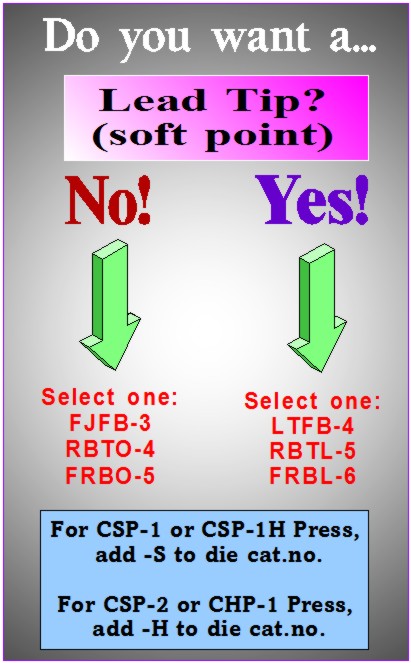

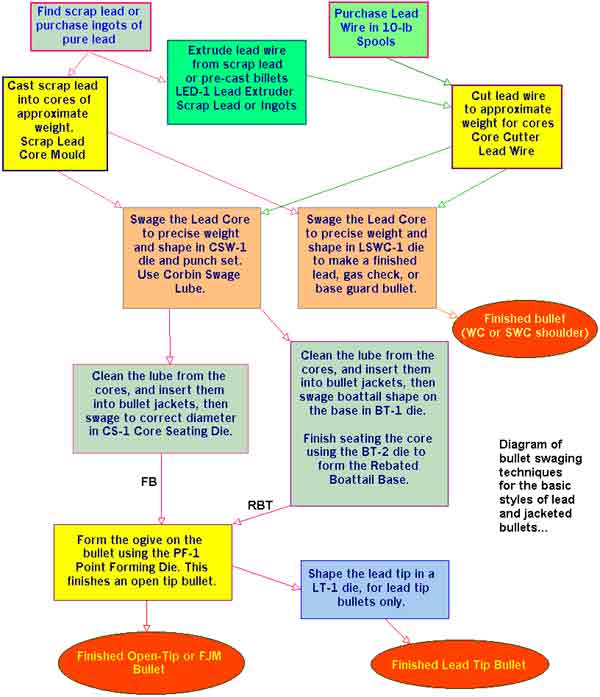

How to Swage Bullets...Quick Chart:

|

Using the Pro-Swage Die:

|

Swaging on a Reloading Press

You can use your regular reloading press to make fired .22 cases into 224 or 243 jackets (with the RFJM-22R or RFJM-6MR jacket maker), and then turn these free jackets into 224 (5.56mm) or 243 (6mm) bullets with a 6-S spitzer ogive, using the BSD-224R or the BSD-243R die sets.

Your reloading press can also be used with the PRO-SWAGEtm PRO-1-R die, to make lead, gas-checked, or Base-Guard tm bullets of the SWC style (small shoulder between the nose and the shank), in calibers from .251 to .58. This is the most precise way to form an economical paper patched bullet. You can order any standard base punch, and any standard shape nose punch, with the die. And it is easy and fast to change shapes of either the base or nose, just by changing the appropriate punch. Weight is fully adjustable, so you get the equivalent of hundreds of moulds with just one swage die!

|

|

Shotgun Slugs and Lead Bullets:

|

|

Extremely high performance shotgun slugs can be swaged using type -H Corbin Swage dies. Some of those shown above include slugs formed entirely from compressed shot (see partly crumbled nose, done to illustrate the construction) which burst apart after impact and limit penetration; slugs with copper or brass inserts; slugs with airfoil surfaces sufficient to spin and stabilize the projectile; high velocity slugs with 44 caliber bodies and fins designed to pass through choked bores safely, catching the muzzle blast gasses to give the slug its initial spin; multi-part slugs with hard and soft lead segments; slugs designed to fit perfectly into specific plastic shot-wad inserts like a sabot (a 20 gauge slug can fit some 12 gauge wads, acting like a saboted slug without the expense of special components); and other exotic designs.

|